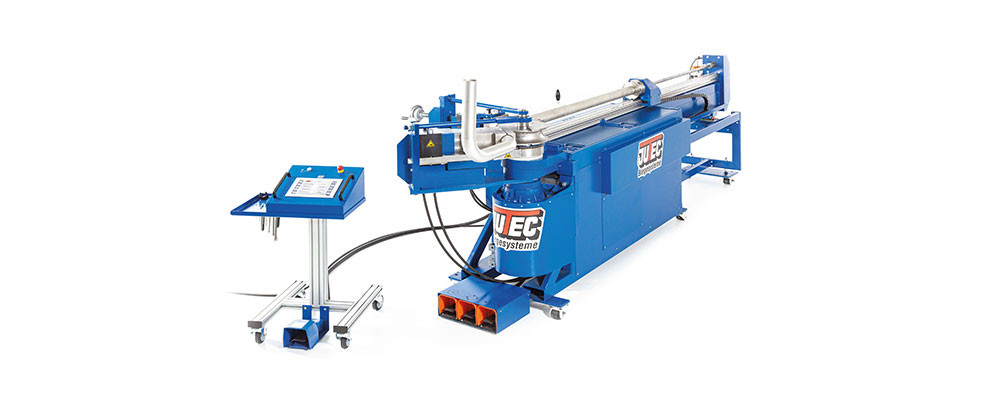

Bending systems 7000 and 9000

The cost-effective bending machine for narrow bending radii

For tube dimensions of 20 mm to 90 mm this bending system offers solutions for complex geometries with standard radii of 2xD. Depending on material quality and wall thickness ratio also radii of 1.5xD can be realised suitable for series production. At a tool height of 120 mm there are also sufficient possibilities for special profiles.

The extremely precise and strong electric drive of the bending axis and the stable and rigid construction of the mandrel support and the bending arm contribute also to the desired bending result.

The pluggable bending tools enable quick retrofitting for bending other tube dimensions. The locking clamp pressure for tube clamping can be optimally adjusted. The SPS control with data storage and latest X2X interface can store over 1000 programs (can be expanded via USB stick) for bending angle, linear measure and torsion angle for a maximum of 50 bending sequences at one tube length. A freely programmable database up to 500 of materials is available for monitoring the elastic recovery values.

The machine disposes of two operational modes: In “simple bending” length and torsion of the bends towards each other are automatically displayed. In the mode “controlled bending” the data is stored beforehand and a permanent nominal/actual comparison is made during bending.

Also available with pneumatic rotation stopper or with gear-assisted length and twist positioning.

Possible fields of application:

- hydraulic piping

- pipeline construction

- plant construction, e.g. chemical industry

- metal construction

- prototyping

Technical data:

bending capacity 7000: Ø 20 to 70 x 5mm

bending capacity 9000: Ø 20 to 90 x 5mm

depending on material

- bending radius min/max: 40 mm/250 mm

- bending radii min: 1.5 x Ø (standard 2 x Ø )

- multi functional machine control setting of bending angle (0,1°)

- mandrel support lengths 3000/4500/ 6000 mm

- bending result 180º max

- weight 1,600-3,200 kg (depending on type of construction)

Optional accessories:

- automatic mandrel lubrication (minimum quantity)

- pneumatic or hydraulic quick chuck

- higher bending radii up to 300 mm

- positioning of length and torsional twisting via automatic braking function or by means of manual catches via pedal switch

- semi-automatic positioning of length and torsional twisting via stepper motor– automatic tool retraction

- tube calculation software

- frequency converter for the bending axis

- 10” touch screen with integrated tube calculation

- data transmission via cable (LAN), radio communication (WLAN), or USB

Contact form

You want to bend other tube dimensions?

- For tube dimensions up to 50mm please have a look at the bending system 4800.

- For tube dimensions up to 50mm please have a look at the bending system 5000.